What Is FRP (Fibre Reinforced Plastic) Where Is It Used?

When the word “plastic” is mentioned, most people think first of all of everyday household items like containers or pipes, packaging and plastic wrappings. But Fibre Reinforced Plastic (FRP) is in a whole different ball game class. It’s strong, it has a remarkably long life and is meant to be used in conditions where most materials fail at the hands of corrosion or moisture.

Yet, today, that same magic material is under the radar—quietly taking over for steel, concrete, wood and aluminum across multiple industries but still a conglomerate à clef to many. So let’s unpack this thing in layman’s terms.

What Exactly Is FRP?

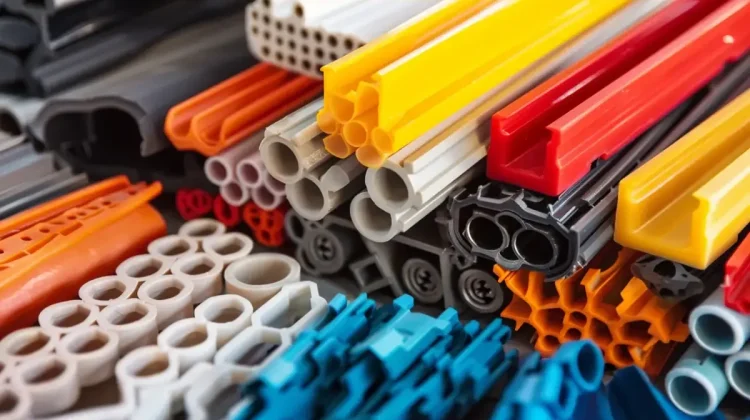

FRP is a composite material. This means itʼs built from two primary parts:

Reinforcing Fibers – Typically strands of glass fibers

A Resin System – e.g. polyester, epoxy or vinyl ester

The fibres give the material its strength, and resin binds everything together and guards against chemicals and the whims of nature. It’s like steel bars within concrete — each supports the other.

The result is a material having:

- Strong

- Lightweight

- Non-corrosive

- Weather-resistant

- Long lasting

This makes it ideal where metals would corrode or concrete substrates require protection.

Reasons to Choose FRP Over Conventional Materials

Other industries have used metals and concrete for decades. But those materials carry predictable issues:

| Property | Steel | Concrete | FRP |

| Corrosion Resistance | Poor | Moderate | Excellent |

| Weight | Heavy | Very Heavy | Lightweight |

| Custom Shapes | Difficult | Limited | Highly Customizable |

| Maintenance Required | Frequent | Medium | Very Low |

Add in things like the corrosive effects of salty air, chemicals or moisture with wastewater exposure and FRP is clearly the more cost-effective choice.

How FRP is Made During Pultrusion

Though the process can vary depending on how it’s made, here are the basic steps:

- The fiberglass mesh layers the mud up.

- Resin is spread and left over the fibers.

- The sheet or component is formed in a mold or hand-pounded.

- The material is then cured (hardened).

- Surface finish and gage checks are in place to assure quality and durability.

It’s a controlled process that lets companies fine-tune shape, size, thickness and strength — things metals and concrete can’t always do well.

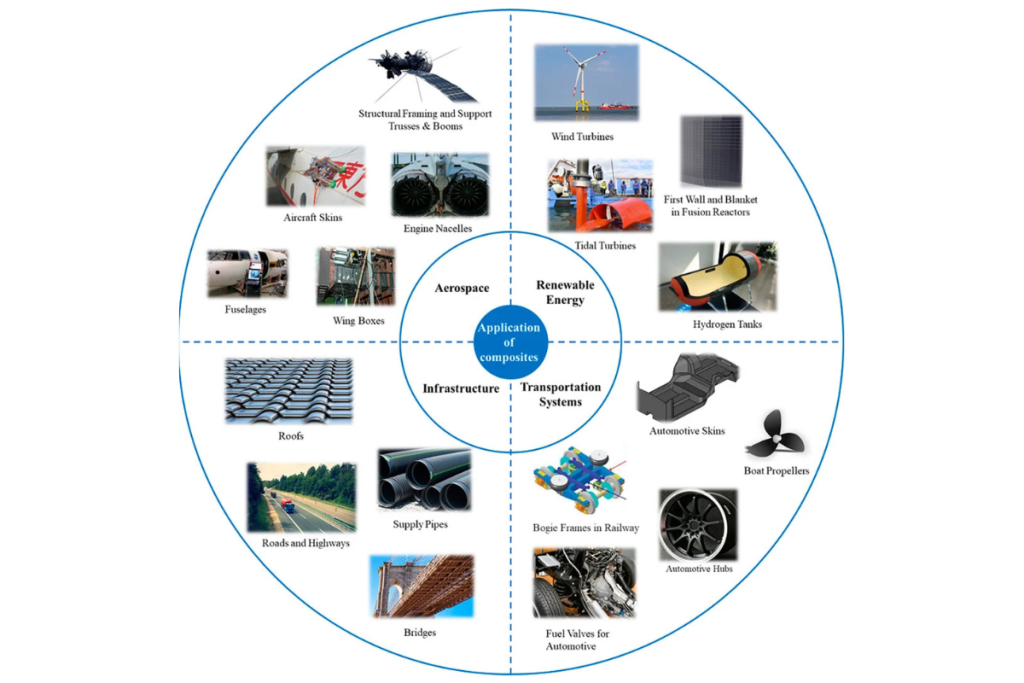

Applications of Fibre Reinforced Plastic in Real-Life

FRP is much more prevalent than most people think. Some everyday applications include:

- Water & Wastewater Industries – FRP tanks, scrubbers and components do not corrode when exposed to water — even saltwater or chemically treated water.

- Chemical Processing Plants – Where liquids and gasses would quickly eat away at steel, FRP remains functional for years.

- Building Construction – Architects can employ FRP sheets and cladding panels to design façades that are wonderful to look at and require virtually no ongoing maintenance.

- Landscaping and Urban Design – Quality and stylish FRP planters and pots are trending because they are light, weather-resistant, and modern—ideal for gardens, hotels, commercial plazas, and rooftops.

- Marine & Coastal Use – FRP is also not affected by salty air or sea water, so it can be used in boat houses and on bridges near saltwater.

Why FRP Is Being Adopted By Industries So Fast

Businesses today want materials that:

- Last longer

- Require less maintenance

- Reduce downtime

- Lower lifecycle cost

FRP fits well with all of the above.

While the upfront cost is sometimes a little more expensive than plain metal, the long-term cost of ownership is significantly less since there’s no rusting, repainting, fixing, or replacing.

Guide On Selecting A Good FRP Manufacturer In India

When you are in search of industrial FRP, take these ideas into account:

- Do they provide custom design help?

- Is there a kind of quality control?

- Are the ingredients traceable and certified?

- Are there any other installations in your segment?

A reputable manufacturer will always direct you to the appropriate resin version and structure thickness suitable for your use environment.

Conclusion

FRP has long since ceased to be a “specialty” material. Today, it is a very practical solution for industries working with moisture, chemicals, weather exposure, or just demanding long-term durability. It provides the strength of metal with none of its weakness and alleviates maintenance headaches that accompany concrete.

When you are searching for FRP products for your industrial, architectural, or landscaping project, there is a big difference in manufacturers.