FRP Benches

Effy FRP Solutions is a trusted name in the production of high-performance Fibre Reinforced Plastic (FRP) benches in India. Manufactured using advanced pultrusion technology—a continuous process that reinforces fibers with resin and cures the material through a heated die—these benches are engineered to deliver exceptional durability, strength, and long-term performance. This method ensures the creation of high-strength composite profiles with uniform cross-sections.

Unlike traditional materials, Effy’s FRP benches are resistant to corrosion, rust, and environmental ageing. While wooden benches are prone to decay, iron to rust, aluminium to oxidation, and cement to cracking, our FRP benches remain unaffected making them an ideal long-term alternative. Their reliability and low maintenance make them an excellent replacement for marine wood, timber, cement, iron, and aluminium seating.

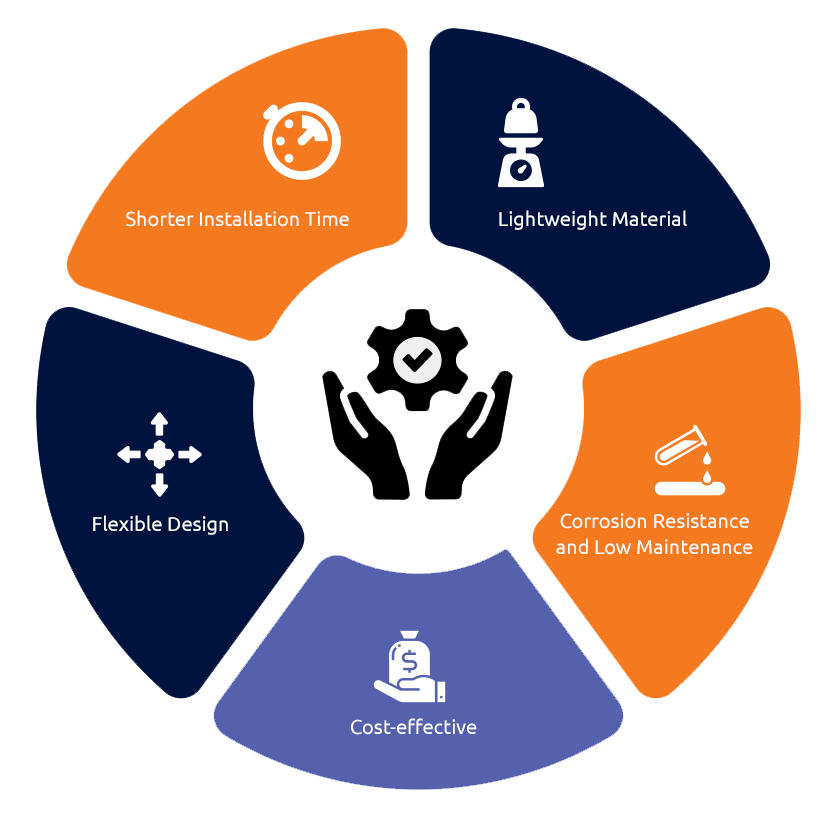

Why Effy FRP?

Advantages of FRP Benches

- High Strength-to-Weight Ratio: Pultruded FRP offers exceptional mechanical strength while remaining lightweight and easy to handle.

- Corrosion Resistant: Ideal for outdoor and coastal environments, withstanding moisture, chemicals, and weathering without deterioration.

- Design Versatility: The pultrusion process enables the production of complex shapes and customized profiles to meet diverse design needs.

- Low Maintenance: Resistant to wear and environmental damage, reducing the need for repairs and lowering long-term costs.

- Cost-Effective: More economical than wood, steel, aluminium, and cement benches in terms of maintenance, durability, and lifespan.

- Structural Integrity: Maintains performance and strength under regular use and heavy load conditions.

- Thermal Stability: Withstands temperature fluctuations without losing form or function.

- Non-Conductive: Provides electrical insulation, enhancing safety in public or industrial environments.

- Precision Manufacturing: Offers dimensional accuracy and consistent quality for reliable performance.